Method for pretreatment etching and smut removal before anodizing titanium

I have written an article on how to DIY titanium anodizing at home, but pretreatment is a very important factor in the success of anodizing.

If titanium is not treated firmly by pretreatment, it will not color beautifully, especially at high voltages.

The influence of the pretreatment changes depending on which grade it is, whether titanium alloy or pure titanium, or pure titanium.

This time, we will introduce the method of etching and smut removal, which is a pretreatment of anodizing titanium.

About the type of titanium

There are many types of titanium used in the world even if it is said titanium.

Industrial pure titanium

First of all, it is pure titanium.

Titanium used for industrial use and the purity of titanium seems to be called like this.

This industrial pure titanium also exists as four types of standards, and each seems to have different features.

“Titanium" can be 3D printed with DMM.make, but it is this industrial pure titanium, two of which fall under.

Titanium alloy

Titanium mixed with other metals.

There seem to be five kinds of patterns depending on the composition of the metal.

DMM.make enables 3D printing of titanium alloys called 64 titanium.

I use DMM.make “Titanium" when creating titanium accessories. The finished product has a fairly rough surface, but you can also make it mirror gloss by polishing it yourself.

I think that there is probably a method of cutting out titanium and making accessories, but in any case, the difficulty and color tone of the anodizing will change depending on the material used, so please check the material of your titanium in advance.

I think that this site is well settled about the material of titanium.

What happens if you don’t do etching or smut removal?

Before moving on to the specific method, I would like to confirm why etching and smut removal are necessary.

The reason why such a thing is necessary is “Because it does not color beautifully" if this is not done.

To be precise, it is because it does not color beautifully at high voltage.

It colors beautifully even if it does not perform etching etc. up to about 50V. (Yellow around 50V, blue around 30V)

However, it only becomes a grayish-yellow color in the part which exceeds 50V. It becomes pink and purple around 70V, blue purple around 90V, green around 100V, but this etching and smut removal are very important when trying to produce these very vivid colors.

However, this also changes depending on the material of titanium, and in the alloy called TC-4 titanium, it colors beautifully even if there is no etching etc.

If your titanium is not pure titanium, you may not need to be so nervous.

What happens if you don’t remove smut?

The word smut removal has appeared several times so far, but smut is fine black powder that occurs when etched.

Titanium melts when etched, but it seems that a small amount of impurities contained in it remain unsolved by etching, or melted titanium recipitates and becomes such black powder.

If you anodized this black powder with it left, the color will come out, but it will have a blackish finish overall.

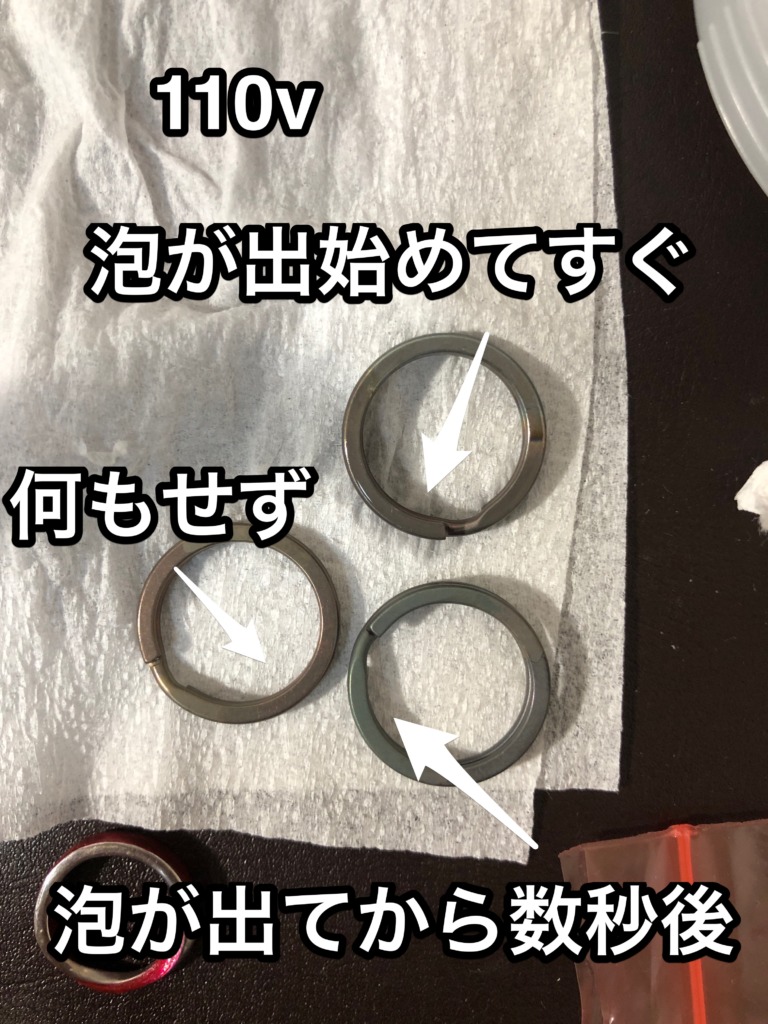

The lower left of this photo is the one that 110V was put without etching. At 110V it usually turns green, but this is not green and is black overall.

The lower right is the one that it applied 110V after etching enough. It has a greenish color, but it is blackish overall.

This is because the smut generated during etching has not been removed.

Therefore, after etching, it is not possible to anodize beautifully unless smut removal is done.

Method of etching

Let’s explain the specific method. First of all, it is etching.

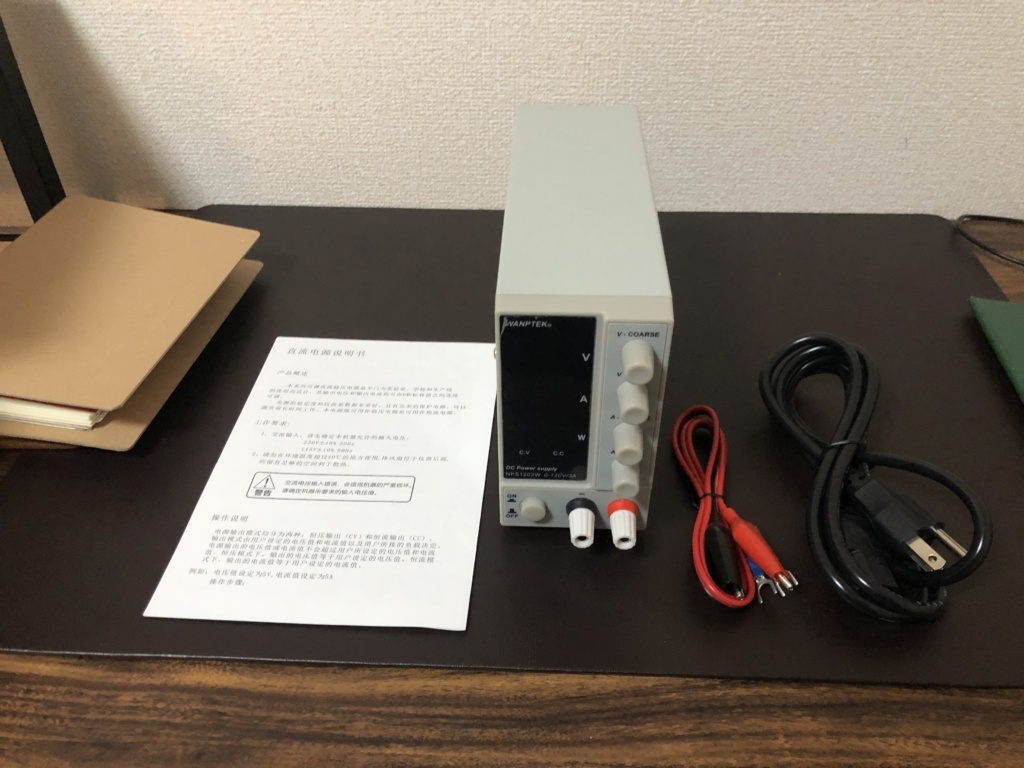

What to prepare

manner of doing

In this 1 minute, simply put an appropriate amount of glitter in a resin container and put titanium there.

If you use a metal container, it will react and corrode, so let’s make it a resin.

I use ziplock containers that are sold at every supermarket.

Depending on the surface processing of titanium, foam occurs after about 1 to 2 minutes.

This causes titanium to melt and hydrogen is generated by fluorine under acidity.

More detailed methods and reaction formulas are also written in the following formulas, so please take a look at them.

In the case of anodizing again, it is good to put it until the color of the surface disappears.

When etching normal materials, transfer them to water after about 5 seconds after the foam starts to appear.

How to remove smut

What to prepare

manner of doing

Use oxidol to remove smut.

I mix 50 ml of glitter with oxidol in 1 minute and put it in a ziplock container.

It may be hard to understand because it is a GIF, but please see how the change is.

Two types of rings are placed in the mixture of glitter in 1 minute with oxidol, but the right side contains a thing with smut after etching.

It is about 30 times faster, but can you see that the black smut disappears in about 10 minutes and it is white?

Oxidol contains hydrogen peroxide, but this hydrogen peroxide creates titanium and complexes, and stabilizes when titanium dissolved in the liquid melts.

It seems to be a mechanism that the fluoride contained in the glitter melts titanium in 1 minute, and the melted titanium reacts with hydrogen peroxide and remains melted, so it does not recipitarate and smut does not come out.

The reaction between hydrogen peroxide and titanium is described in the reference, so if you are worried, please see.

If you want to dissolve titanium anyway, why don’t you suddenly put it in this “oxidol + 1 minute kirari" mixture solution? You may think, but the speed at which titanium melts seems to be different.

Therefore, it seems to be more efficient to etch only with glitter in 1 minute at the beginning.

If etching and smut removal are performed as described above, the ring of pure titanium in front will be such a color.

Since the ring was applied to the solution by half and anodized, the vicinity of the interface is not so beautifully oxidized, but the green, which is a high voltage color, is also firmly colored.

That’s all.

If you are trying to perform anodizing titanium, I think that it is better to perform these pretreatment reliably, and you can anodize beautifully.

The method of anodizing is summarized in this article, so please take a look at it.

Chemicals with a higher concentration

The chemicals introduced this time are small in quantity and the price is low, so it is recommended for those who want to try it easily, but it is easier to do chemicals with higher concentrations.

I’m glad if you can see it together because I summarized it in this article.

Bibliography

Development of colored titanium and its application to the field of architecture and decoration

Discussion

New Comments

No comments yet. Be the first one!