How change the titanium color when you quenched with a burner?

Did you know that roasting titanium with fire changes to various colors?

It is also said that titanium blue, but in fact, a metal called titanium has an oxide film when roasted with fire, and it seems to change to various colors.

I’ve created several titanium accessories so far, and I wondered if I could use this property to color them.

This time, I actually tried it, so I would like to introduce how the color changed.

- 1. Why titanium is colorful

- 2. prepared to make an oxide film

- 3. Color changes

- 3.1. Before machining

- 3.2. Burner, about 40 seconds, yellow.

- 3.3. Burner, about 68 seconds, purple.

- 3.4. Burner, about 76 seconds, pale.

- 3.5. Burner About 118 seconds Part red, yellow

- 3.6. Burner about 175 seconds Gradations such as red, blue, white, etc.

- 3.7. Burner about 241 seconds Gradations such as red, blue, white, etc.

- 4. How to dissolvate the oxide film

- 5. It is difficult to control the preparation of oxide film with a burner

Why titanium is colorful

When titanium or stainless steel are heated to high notes, it changes to a bright color.

I think that there are people who have seen what is changing blue with a muffler of a motorcycle, but this is also the one that the metal was colored by the same principle.

These are the result of the resulting oxide film of the metal.

There may be an image that the coin turns brown when you hear it as an oxide film, but when it comes to titanium, etc., it becomes a vivid color thanks to the oxide film.

How it works is the reflection of light.

The ability of an oxide film interferes with the light that hits titanium, and the color looks different depending on the wavelength that interferes with it.

The wavelength of the light that interferes with the thickness of the oxide film changes depending on the thickness, but when titanium is heated with a burner, the oxide film grows and the color changes as the thickness becomes hot.

I thought that I would color accessories using the properties of titanium.

I thought it would be very cool if I could make accessories of such a color because it would be a really vivid color such as blue and red.

Titanium accessories are created by creating 3D models with an iPad app called shpar3D and 3D printed on DMM.make. Learn more.

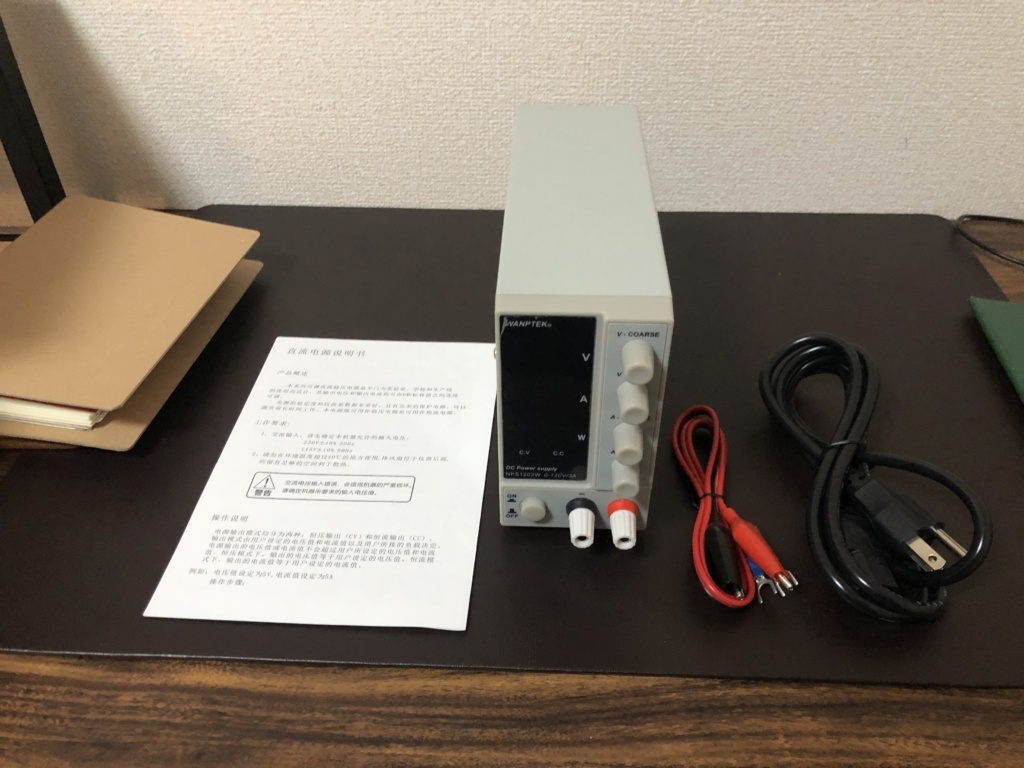

prepared to make an oxide film

Well, here is what I prepared to make the oxide film.

- Torch Burner

- Ceramic Board

- Carbon protectors

- plate

- turntable

- chopstick

- digestive organ

I will introduce each one in detail from now on.

By the way, if you are thinking of heating titanium with a burner in the same way, please be careful about the handling of fire enough.

Keep the digestive system close at all times, and flammables not to be nearby.

I think that it is better not to use disposable chopsticks because it is easy to burn, but I use it without any way so that the turntable does not melt.

Anyway, please be careful enough.

Torch Burner

The main role of processing is the burner.

I used a torch burner of the type that can be attached to the cassette cylinder used for the cassette stove etc. used when the pan is used.

Basically, I think that it is good with the favorite one because the handling etc. are the same in any burner.

I used a type of thing that is also used to broil a dish.

The burner purchased at this time is also used when brazing rings, bangles, etc. by processing wires and plate materials such as brass, copper, and silver.

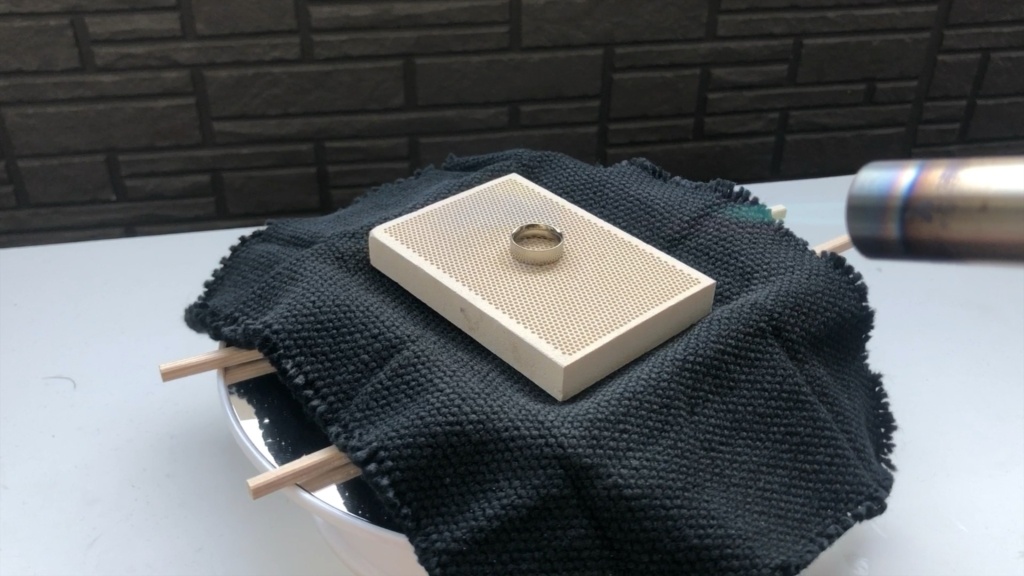

turntable

As explained at the beginning, the oxide film is grown and colored by heating.

I thought that the temperature could be uneven when it was a burner, so I prepared such a turntable to apply as uniform heat as possible.

It is a turntable used for shooting figures.

As a result theory, even if you use this turntable, you may not have to have uneven coloring.

plate

It is a plate for placing ceramic boards.

I thought that if I put the ceramic board directly on the turntable, it would melt in the stone, so I put the plate in between.

I put disposable chopsticks because I wanted to create a space between the turntable and the plate to prevent heat from passing to the turntable.

Ceramic board, carbon protectors

Ceramic board for brazing of metal.

It is better to have such a ceramic board when handling fire.

In addition, a carbon protector made of carbon fiber is laid under it.

This will prevent you from the fire, and it will increase safety because it is difficult to burn in itself.

I think this ceramic board and carbon protector are essential when dealing with burners.

Color changes

Well, I will introduce the change when it was actually broiled with a burner.

By the way, it is thermal power, but the amount of gas is the least.

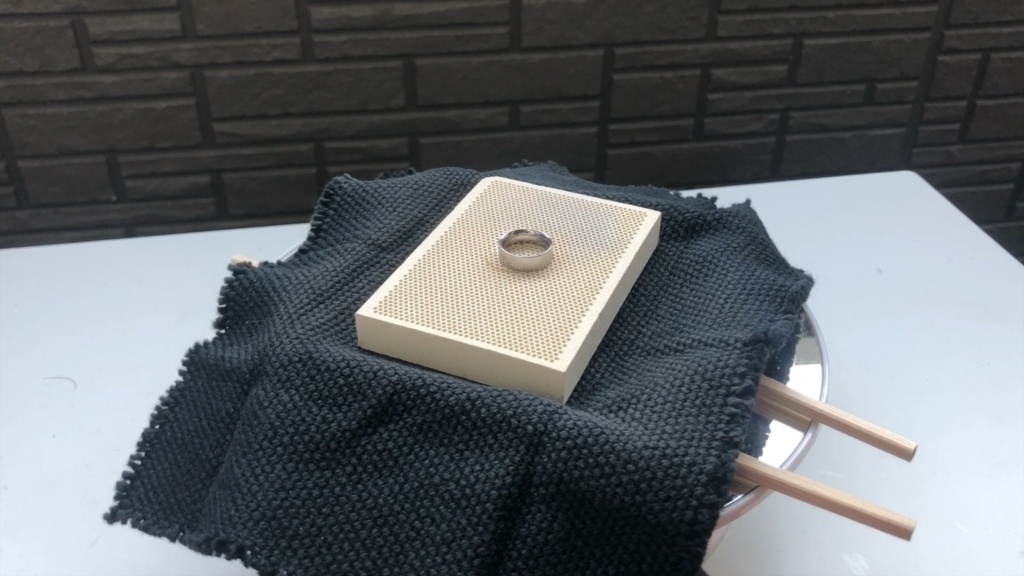

Before machining

It is a color like this before processing.

It is washed with household detergent before processing.

In fact, it was better to apply it to acid and clean the surface chemically, but I did not do acid treatment because I did not prepare just the right acid.

This is a ring of titanium mirrored in this article. If you are interested in mirroring, please also check out this article.

Burner, about 40 seconds, yellow.

I broiled it with a burner while turning the turntable and it became slightly yellowish in about 40 seconds.

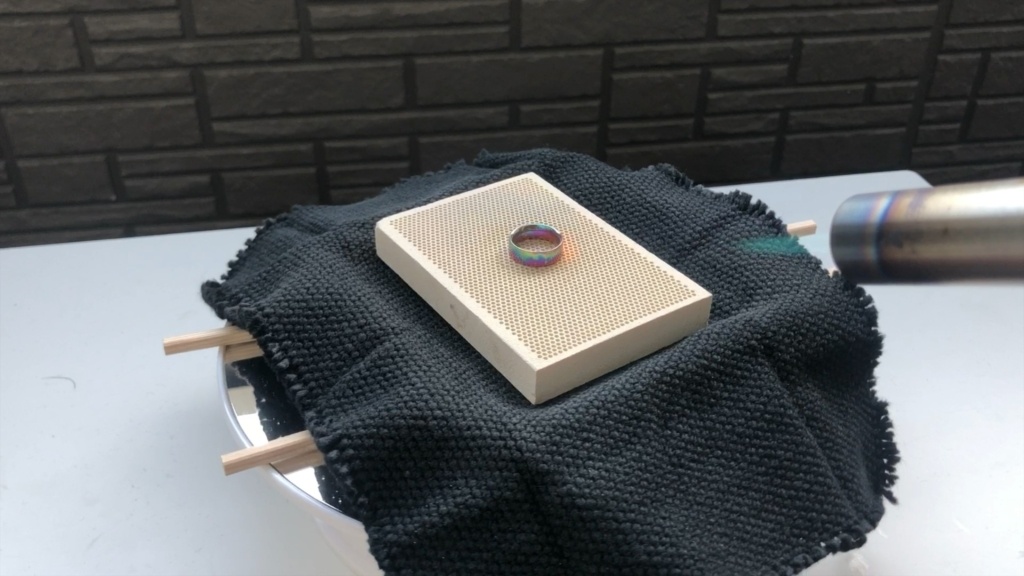

Burner, about 68 seconds, purple.

As soon as it became yellow, the whole became reddish and purpleish.

Burner, about 76 seconds, pale.

After purple, it turned blue, and it became a color that seemed to be whitish partly.

At this time, there was a part where the color was whitish in a point shape because of oil stains or something on the surface.

I think that the color of this stage was the most colorful and beautifully colored.

Burner About 118 seconds Part red, yellow

When heated further, a part becomes red, and a gradation with yellow occurs from there.

Burner about 175 seconds Gradations such as red, blue, white, etc.

If you continue heating, the whole gradation will be red, yellow, and blue.

Burner about 241 seconds Gradations such as red, blue, white, etc.

If you continue heating for another 3 minutes from there, the feeling of the gradation will change slightly, so that there will be no major change.

Therefore, we stopped heating at this stage.

When I look at the photo, I get the impression that this is this with a beautiful gradation, but the real thing is dull and it was not very beautiful.

How to dissolvate the oxide film

I think that it is likely to feel, “It only had to have stopped there" when anodizing like this.

In such a case, it is good to shave the oxide film, but if it is dissolved with chemicals, time can be shortened.

The drug is also readily available on the Internet.

It is difficult to control the preparation of oxide film with a burner

How was it?

When titanium was heated with a burner, such a color change was made.

I really wanted titanium oxide to be beautiful white, but it doesn’t seem to be like that. (Titanium oxide is also used as a pigment of white paint.) )

In the case of burners, the heat cannot be evened by all means, and it seems to become uneven in color like this.

I feel that I can use it as an accessory even if there is such unevenness, but I personally have the impression that I can not use it very much.

If you want to achieve beautiful color development, it may be better to use methods such as electrical anodizing.

Anodizing is summarized in this article, so please take a look at it together.

Discussion

New Comments

No comments yet. Be the first one!